Starting to put things back together. A few small areas of corrosion needed attention, but everything is now ready to be reassembled and wired. I have reinstalled the cleaned and overhauled ventilation ducts for the forward panels, and new ducts for the gasper outlets are on order, as many of

In the cockpit, I was able to heat it to 15-20° to prime the forward bulkhead. Apart from some small spots corrosion works are now complete! The next step is to put back the insulation and the restored ventilation ducts and I have been studying the AC and Gasper system

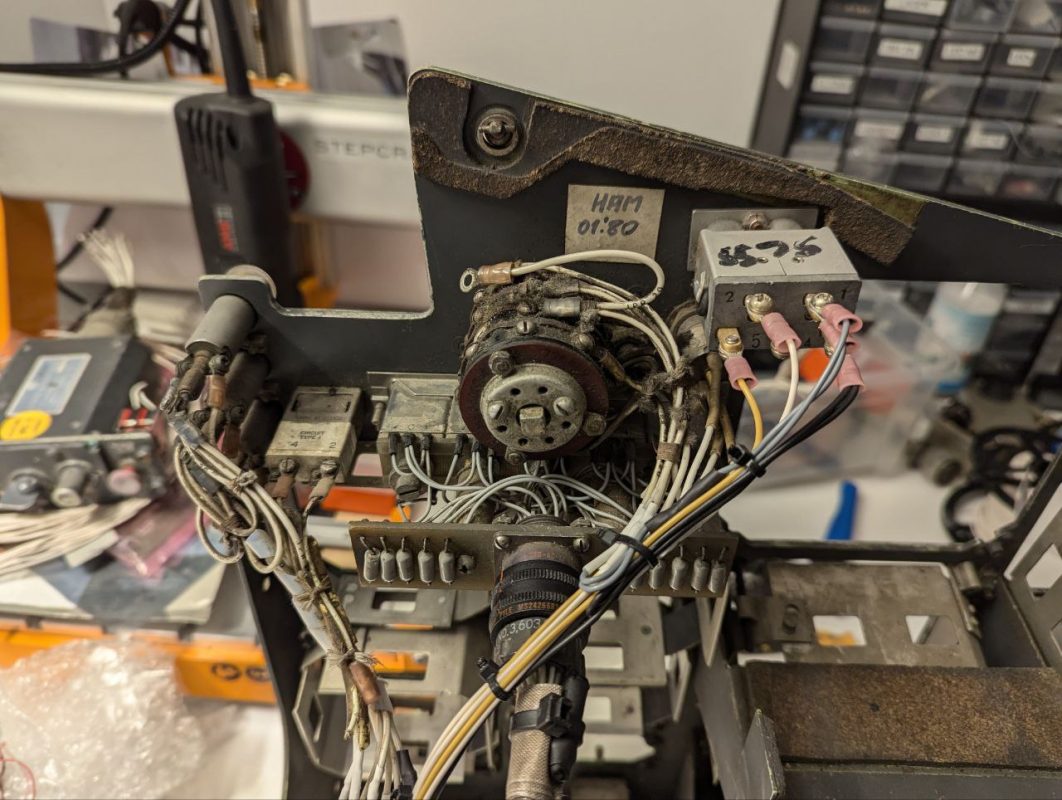

Autopilot, which was halfway finished for a long time, has now been completed and tested. The problem was the pitch wheel assembly is a rather complex design with solenoids and resetting potentiometers I just could not figure out how to interface so I decided to strip everything and place 360°

As the project progresses, I anticipate major financial obstacles in getting the cockpit to a fully functional simulator in 2025. Just the electronics (excluding Computers) needed to operate all of the 136 instruments, 373 switches, 231 lights, and relays total 4833.60 euros, not including the 2000 euros I’ve already spent

Corrosion is by far the biggest challenge in this project apart from financing. Brushed off the corrosion on the RH side and the forward bulkhead and repainted with 2k primer. Once the forward bulkhead is complete I can reinstall insulation and air conditioning ducts and basically start wiring things up.

painted the front in black matte, replaced the broken wiper motor, worked on the autopilot, flight director INS, overhead and captain panel, and audio warning systems. Usually spent 2 hours a day whenever possible. I usually spent two hours per day on the 707 project, if possible. The autopilot is proving to be a bit of a challenge, despite its simple appearance. The center component of the Autopilop contains a motor that shifts a potentiometer into neutral position following disengagement

On the move again… moved D-ABOD’s cockpit to her temporary new home right next to my home. This will