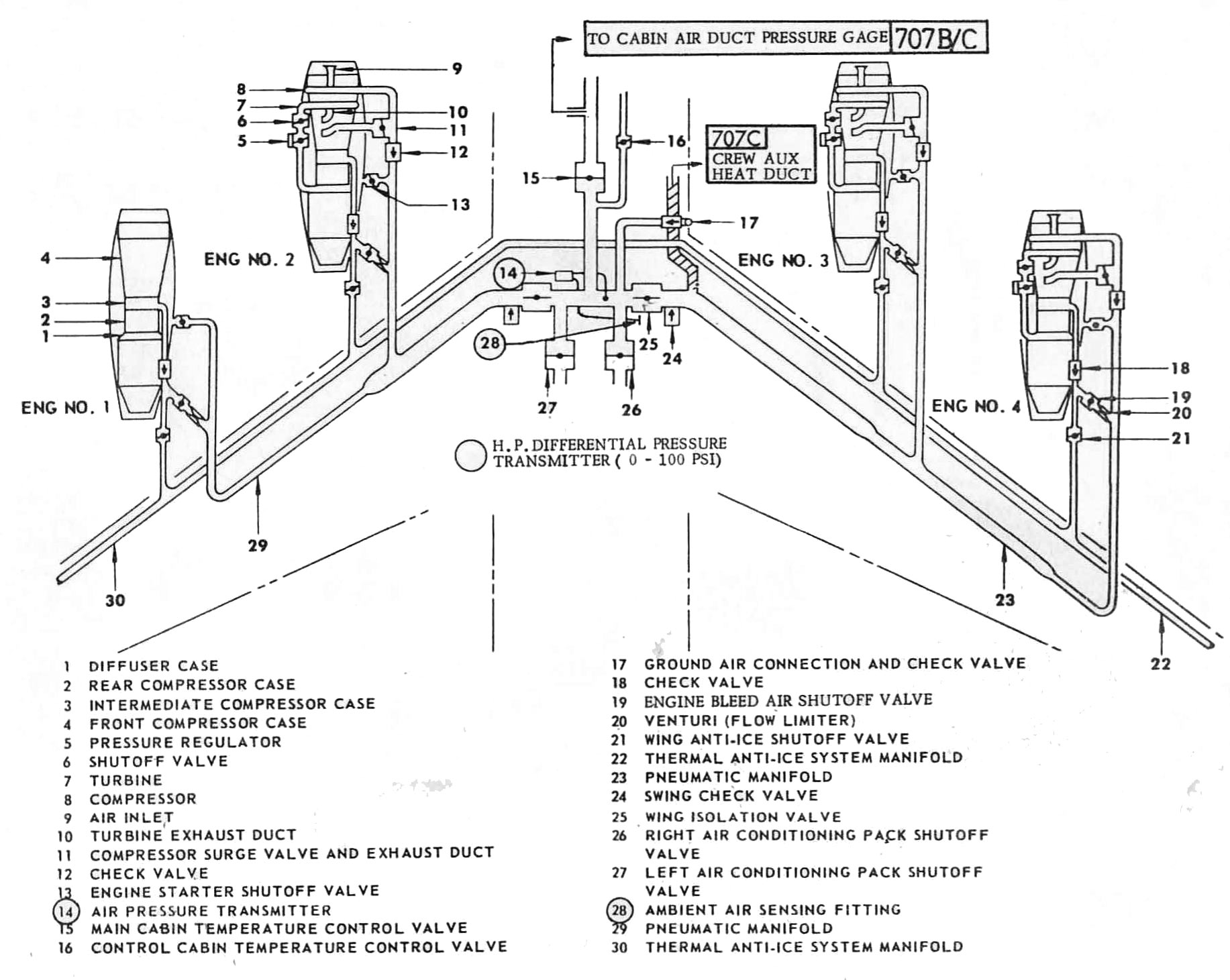

The pneumatic system supplies high temperature compressed air for air conditioning and pressurizing the airplane and for low pressure engine starts. The system consists of turbo compressors mounted on engines No.2, 3 and 4 and low pressure bleed air from all f our engines. The main air supply is obtained by compressing fresh air in the turbo compressors. The air enters through a ram inlet on top of the engine nacelle. The turbo compressor is driven by bleed air from the last stage of the high pressure compressor (N2) of its respective engine. After a turbo compressor is put into operation it is independent and self-governing. An alternate air supply is obtained by bleeding low pressure air (N1) from the intermediate compressor case of each engine. The bleed air system consists of appropriate ducting, a shutoff valve and a flow limiting venturi. The compressed and heated air from each turbo compressor as well as the engine bleed air is routed through the left and right wing manifold and crossover pneumatic duct to the air conditioning system.

Turbo Compressors

The turbo compressor uses energy of engine bleed air (16th stage) to drive a compressor which sucks in outside air, compresses it, and sends it in for cabin pressurization and heating

TURBO COMPRESSOR SWITCH

When a Turbocompressor switch on an operating engine is momentarily moved to START, a latching part of the switch arms the turbocompressor overspeed trip light and the momentary part of the switch signals the regulator valve to open, which starts the turbo compressor. When the start switch is released, electrical power is removed from the regulator valve and air pressure which opened it now holds it open. This means that an electrical power failure will not stop an operating turbo. If electrical power is lost on an operating turbocompressor, the overspeeed protection will work but the trip light and the oil low Pressure light will not. The low oil pressure light is armed any time normal DC is available.

BLEED AIR PRESSURE REGULATOR

Engine bleed air pressure varies with thrust lever changes,so the bleed which drives the turbo first passes through a pressure regulator to obtain a more stable pressure source. This regulator also serves as the turbocompressor start-stop valve. When the turbo switch signals it to open, engine bleed air provides the operating force for the valve to operate, so its engine must be running. When the turbo switch is released, electrical power is removed from the valve. While engine bleed pressure is higher than the regulator setting, its valve modulates to supply more constant, but reduced, bleed supply to the turbine of the turbocompressor. This allows some throttle changes within the mid to higher thrust ranges without affecting turbocompressor outputs. As engine thrust is reduced, the regulator opens wider to supply, more of the low pressure bleed. When engine bleed pressure becomes less than the regulator setting, it opens fully but turbocompressor output ‘starts to diminish. If air pressure to the turbo becomes excessive, a shutoff valve downstream from the pressure regulator will close and stop the turbocompressor. When pressure returns to normal, the turbocompressor can be restarted in the usual way. The turbo switch stop position momentarily signals the regulator to close but engine bleed air provides the actuating force.

At high thrust settings a turbocompressor will normally be operating under the influence of the flow control, so it will turn only fast enough to put out its rated mass airflow at the existing altitude. However, an altitude can be reached at which turbo RPM will increase to 100% but does not satisfy the flow controller. When this happens a speed limiting system prevents the speed control nozzle from opening any wider bleeding off oil pressure from the nozzle actuator. 100% is normal maximum RPM.

OVERSPEED PROTECTION

The speed topping control serves to limit the speed of the turbocompressor to a preset maximum of 95% (46500 RPM). Should the cabin air compressor over speed a trip mechanism will operate at 112% (56,000 RPM). It can then only be reset on ground.

TURBO GROUND MODE

The flow control system normally limits turbocompressor output to its rated mass airflow. However, this is not enough air for cross-starting engines. Therefore,

when on the ground, ‘its flow control system ts bypassed causing turbocompressor RPM to follow engine RPM. At liftoff the turbo returns to fight mode, which means

its output decreases to rated flow under the influence of the flow control system. The ground mode solenoid is energized, when turbocompressor is ON, the LH safety switch is in the ground

position and one of the engine start control switches is in the GROUND START position. The GROUND START position of these switches is used only during low pressure engine starts.

Normal indications – ground operation

1. Engine idle: 50 to 60 % rpm

2. 80 % N2: 80 % rpm

Turbocompressor RPM indication is independent of aircraft’s electrical system.

Comparison between airflow by B/A & TCs

The airflow delivered by B/A is essentially variable with

– Engine RPM

– Airplane altitude and cabin differential pressure

The influence of these factors on T/Cs airflow is negligible provided:

– Engine RPM is not near idle

– The T/C RPM is below the topping speed

At high cabin differential pressure, the best air flow is obtained by using T/C instead of B/A

- After the engines are started the primary pneumatic source is from T/Cs.

- Normal ops: T/C 2 and 3 ON for take off. Engine bleeds are not to be used for any take off. T/Cs reduce take of thrust.

- Descent: Use all T/Cs. Only use bleeds if necessary.

Pressurization:

Compressed air is supplied by the turbo compressors or the engine air bleeds through the air conditioning

and distribution systems to the pressurized compartments. Cabin pressurization is provided by

controlling the rate at which the cabin ventilating air is permitted to exhaust from the airplane

through cabin pressure outflow valves. Automatic control is provided by a pneumatically operated

cabin pressure automatic controller which allows selecting a cabin altitude from -1000 feet to

+10.000 feet within the differential pressure limit of 8,6 psi; and also provides control of the rate

of change of cabin pressures. A pneumatically y operated manual pressure controller permits rate control

and allows selecting any cabin pressure differential to 9,42 psi should the automatic controller

malfunction. Other system components include filters, pneumatic relays, jet pumps, cabin altitude

indicating and warning devices,

a safety valve, and an electric override mechanism to open or close the outflow valves.

The pneumatic relays alleviate system response time lag. The jet pumps, bleed air operated, provide

a negative pressure source for the automatic and manual controllers and for the outflow. Valves to relieve

the surge effect at the start of cabin pressurization. The jet pumps also assist in depressurizing

the cabin at landing. A cabin altitude warning horn will sound intermittently if the cabin altitude

exceeds 10.000 feet. Positive pressure relief devices protect the airplane against over pressurization.

The automatic controller has a differential pressure relief valve set at 8,6 psi, and each.outflow

valve has a 9;42 psi differential relief valve. Decompression panels are provided in bulkheads

between pressurized sections to provide local structural protection should the airplane become rapidly

depressurized at altitude. Pressure relief valves are also provided in the aft bulkhead of each

lower cargo compartment to equalize pressure with the adjoining compartment.