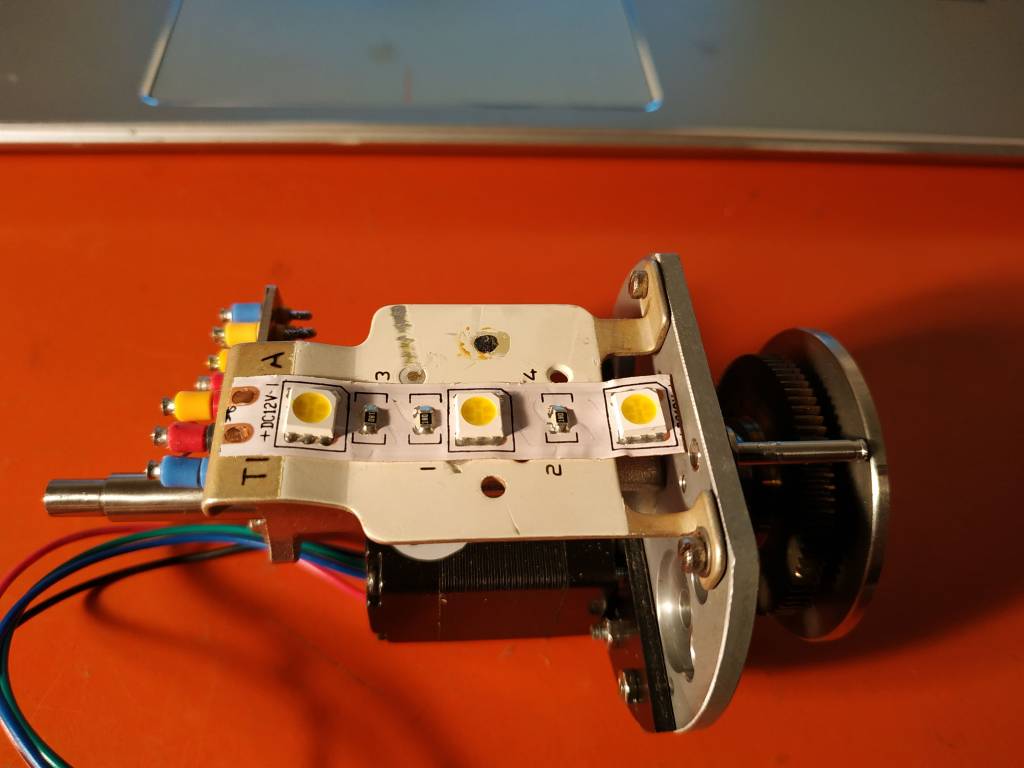

This is a very complex subject and I will be posting articles from time to time on how I do it. These are a couple of photos done recently. As you can see, I do not interface the gauges. I take the original gauge and remove everything behind the dial. This is mostly done in a non-destructive manner making it possible to rebuild the original gauge should that wish arise. Integral lightning is usually original 5V but some gauges that are extremely difficult to open are converted to 12V LED which will probably not require a replacement in the next 20-30 years

The new motors that drive the needles are state-of-the-art stepper motors and drivers used in the automotive and 3D printer industry. This has the huge advantage of needing little to no spare parts (except for flags or dials) and having a maintenance free & highly reliable simulator. And the most important: The precision of these motors is second to none. I did have many gauges for my Caravelle simulator interfaced and spent a fortune on the development and it turned out very disappointing even if the quality of the interfacing itself was good. The gauges were becoming imprecise after a while and some stopped working not because of the interfacing but of the gauge itself of which no spares can be found. This is why I keep telling: Hands off interfacing unless you have lots of spare gauges!