Special guest: My father came over for a 48hrs visit and we had a look at his old workhorse D-ABOD. This was the first time since November 15th 1975 when he flew PHL-BOS-FRA!! He wasn’t very emotional about it and has lots of bad memories flying the 707 with former WW2 pilots and their ‘CRM’ […]

Some progress on the inside and outside of the cockpit of D-ABOD: The tiller finally came off and I was able to remove the CM1 side panel. Some more items from the aircraft’s past came to light. A quick look behind the insulation was rather shocking as heavy corrosion has done severe damage to the […]

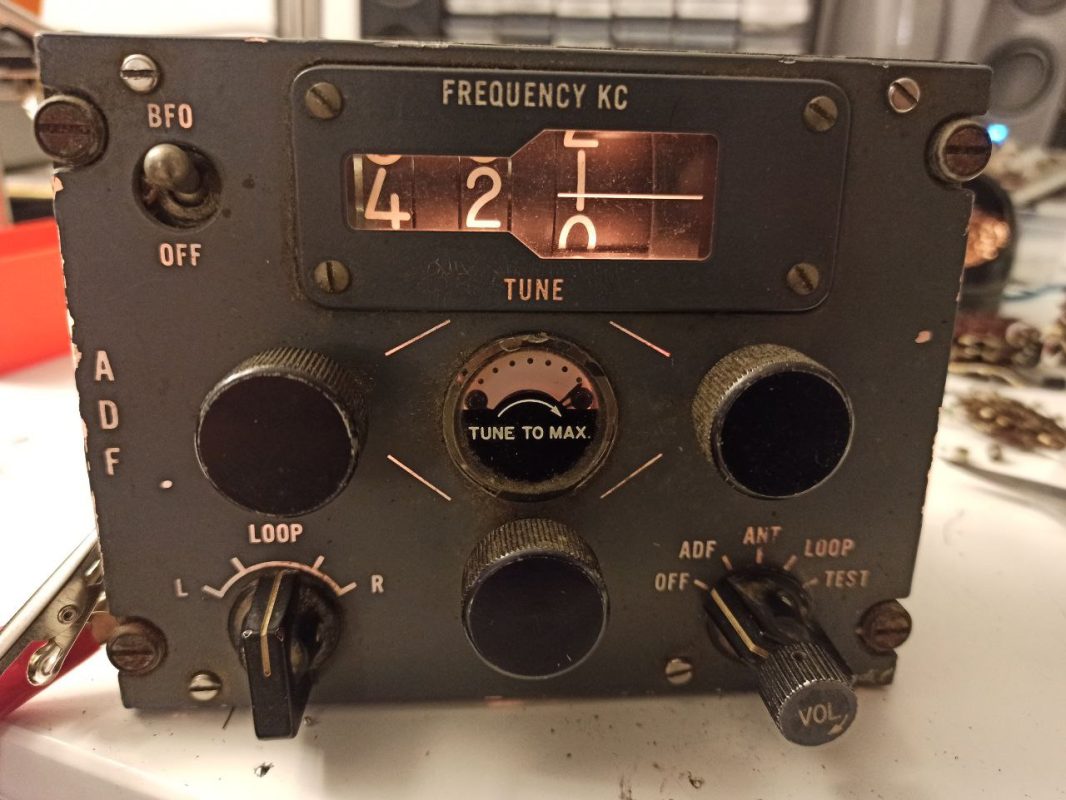

The 2 ADF radios on the control stand are now converted and ready for codeing. I had to replace all bulbs which takes some time as they are soldered to a flexible circuit board. Bulbs are 680 bulbs, by chance I had 80 new bulbs from a previous wrong order. VHF/NAV are next.

YouTube Restoration Video update

Corrosion removal The darkest and coldest time of the year make me focus now on getting work done inside the cockpit such as corrosion treatment and removing the rudder pedal heels. Found a match and cigarette pack wrapping which have been hidden for 50 years or even more. When D-ABOD got retired it only had […]